X 66

North Suburban HAMMOND ORGAN Service

The tone generating process in the X66 starts with a tone wheel generator, very similar to that of the traditional Hammonds but with six notable exceptions. First of all, the main drive shaft runs at 3600 RPM instead of 1200 RPM as it does in the traditional Hammonds. (This is one revolution per cycle of 60 Hz AC power.) Second, there are only twelve tone wheels; third, the wheels are in pairs and run at 6 different speeds. Thus, the generated pitches do not exactly correspond to the equally tempered scale. The result can be called an "X66 temperament," but there is some latitude between theoretical perfection and practicality. The generated pitches are close enough to give a very good sounding result. Fourth, the pitch range is higher, extending all the way up to top B with a frequency of 7902 Hz. Recall that the highest available frequency from the tone generator in a traditional Hammond is 5924.6 Hz. The fifth significant difference is that the tonewheel teeth are shaped more like regular gear teeth instead of the lobe shape found in the tonewheels of traditional Hammonds, and this leads directly to the sixth difference which is the lack of any filtering capacitors and transformers on the top of the tone generator.

Because the signals from the X tone generator are used as reference pitch signals only for an entirely different kind of actual tone generator, there's no need for them to be super-accurate sine waves like those produced in a traditional Hammond tonewheel generator. Immediately after production, they are transformed to square waves by the first section of subsequent circuitry.

Therefore, the generated frequencies from the X66 tone wheel generator are not heard. [In troubleshooting and servicing, a technician may "eavesdrop" on the tone generator outputs with a signal tracer to determine if a particular frequency is missing or a tonewheel pair is running erratically, but that is the only situation in which the signals from the X66 TG are ever heard.] The X66 tone-wheel generator serves as a master reference signal source so that the Hammond company could still advertise that their instruments would never go out of tune. You must realize that although transistors and many solid state circuits and devices were in existence when the X66s were developed in the mid 1960s, a lot of the later technology was still in the future. At that time, accurate crystal controlled oscillators running in the megahertz range and the special frequency dividing circuits needed to derive all of the pitches for a musical instrument from megahertz inputs were not yet used in Hammond organs.

Figure 5.

Meanwhile, Hammond already had by that time over 30 years' worth of proven experience with tone wheel generators and thus using a twelve note master tone wheel generator as the pitch reference for the rest of the instrument made a lot of sense. Here are a few pictures of the special 12 note generator in the X66 instruments. Also different from previous practice was the use of a two-phase, self-starting synchronous motor. Gone were the separate start and run switches and the shaded pole starting induction motors and sliding gears from the earlier Hammonds. Interestingly, the X66 tone wheel generator is not located in the main body of the console but is down in the bottom pedestal section along with the pedal contacts, artificial reverb unit and main console power supply.

Figure five is a look at the special 12 note reference tone generator of an X66. Compare this with the picture of the traditional 91 note generator of a standard Hammond. The only thing on top of this tone generator is a thick felt cover to keep out dust and reduce mechanical noise.

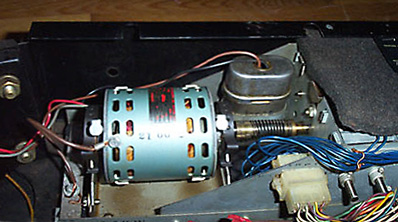

Figure 6.

Figure six shows us the special two phase synchronous motor that runs the main tone generator shaft at 3600 RPM. An oil-filled capacitor [can-like unit immediately to the right of the motor in the picture] is in series with one of the motor windings and shifts the phase of the AC to that winding, therefore the motor is a two-phase unit. AC synchronous motors of 2 or more phases are self-starting. These motors also run smoothly so there's no need of the elaborate spring couplings and flywheels. A simple helical spring coupling is sufficient. On some X tone generators, the spring is replaced by a piece of rubber tubing, but the spring coupling is better.

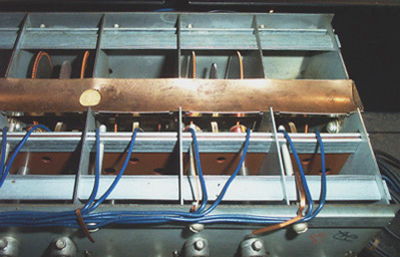

After removing the felt cover you can get a good look inside the tone generator. Figure seven. Two pairs of tone wheels are visible as is the copper oil trough at the top. Immediately under the copper trough is a cloth wick, below which is a steel trough. As in a traditional tonewheel generator, cotton threads connect from the wick to the tonewheel bearings and convey the oil to them by capillary action.

Figure 7.

Previous Page Page 6. Next page